-

Product

-

Encamp Intelligence Platform

Understand, manage, and comply with environmental regulations across all your US regulated locations

-

Waste Management

View and manage all waste streams for all your facilities

-

Compliance Insights

Understand exactly how regulators see your organization

-

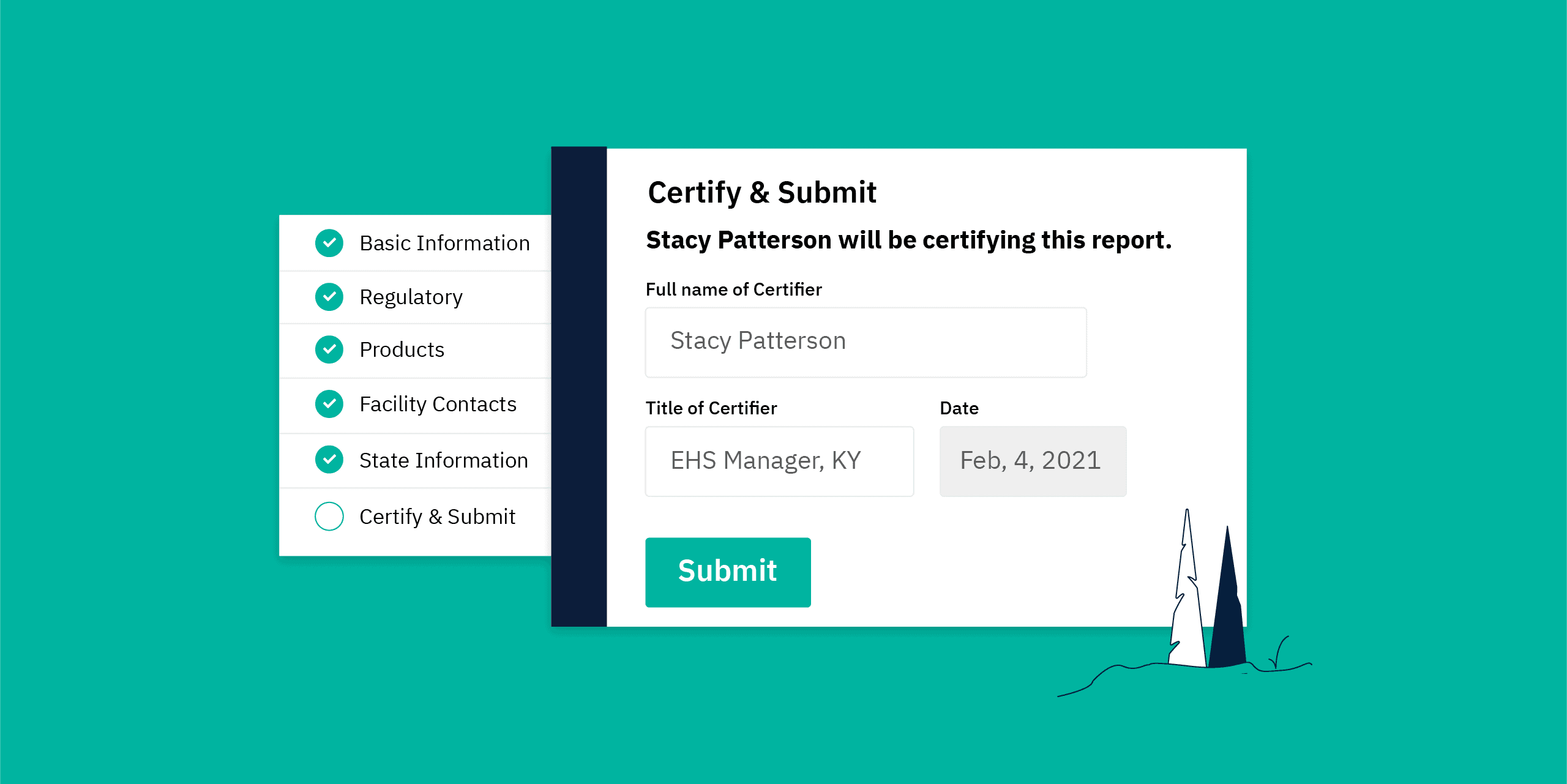

Tier II

Fully automate Tier II reporting and fee payment management

-

HMBP

Achieve and maintain compliance with California's HMBP

-

Task Management

Apply project management principles to compliance

-

Encamp Intelligence Platform

-

Solutions

-

Manufacturing

Achieve compliance and avoid operational interruptions

-

Energy

Prepare for M&A and meet environmental compliance requirements

-

EPCRA

Comply with EPCRA 302, 311, 312

-

RCRA

Get the most comprehensive view of your waste program

-

HMBP

Comply with California's HMBP requirements

-

Regulatory Insights

Your Regulator Eye View for environmental compliance performance

-

Manufacturing

- Customers

-

Resources

-

Resources

All of our educational materials

-

Guides

How to's, checklists, and whitepapers

-

State-by-State Guide to EPCRA Reporting

Instructions for how to file Tier II in all 50+ states

-

State-by-State Guide to RCRA Compliance

Learn how to maintain compliance with RCRA

-

Blog

The latest news, insights, and musings

-

Glossary

New to EHS? Learn the lingo here

-

Webinars

On-demand recordings of live events

-

Customer Education

Application knowledge base, support, and more

-

Resources

-

Company

-

About

What drives us: the Encamp story and mission

-

Customer Success

Unwavering commitment to customers is our top priority

-

Careers

Passionate about the environment and technology? Join us!

-

Security

Our customers’ security is our top priority

-

Press

The latest news and happenings from around the Encampus

-

About