The Company

TopBuild Corp. is the leading installer and distributor of insulation and building material products in the United States. The company is headquartered in Daytona Beach, Florida. Their mission is to provide superior installation and distribution services while maintaining a commitment to safety, sustainability, and customer satisfaction. They have over 415 locations across the United States and Canada. Mason Baziw is the Sr. Manager of ESG and Sustainability at TopBuild Corp. With over 12 years of experience, he oversees environmental compliance for all locations and supports sustainability reporting. He’s a certified safety professional (CSP), U.S. Navy veteran, and resides in Richmond, VA, with his family.

How TopBuild automated their Tier 2 reporting

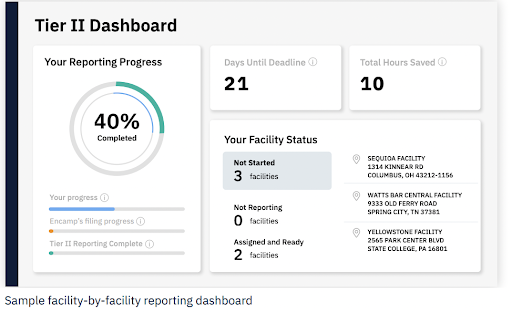

Topbuild has over 400 locations with over 200 Tier II reports to file. Before using automation, TopBuild submitted Tier II reports by aggregating components from different products they used and stored at their facilities. Even though the team met deadlines and maintained compliance, this resulted in a very manual process that was time-consuming for the team –especially around reporting season. Partnering with Encamp enabled TopBuild to automatically aggregate all their data to meet EPCRA reporting requirements in all US jurisdictions, including fee payments. They streamlined all of their facility information to make it accessible and consistent across all their locations and chemicals, increasing visibility and control over their reporting process.

Collecting and Standardizing their data

To harness the power of automation, Encamp ingested the requisite TopBuild facility data on an ongoing basis to ensure TopBuild always has an up-to-date view into their compliance data. Encamp and TopBuild partnered together to develop a data pipeline process that resulted in a standard and consistent data collection process. The implementation of the data pipeline transformed TopBuild’s raw data from their internal Enterprise Resource Planning (ERP) system into data that could now be leveraged for environmental compliance decision making. Encamp also implemented an SDS digitization process to expedite the hazard classification of TopBuild’s products. Ultimately this innovative process allowed TopBuild’s environmental professionals the ability to track chemical inventories, monitor triggers in reporting thresholds, and determine reportability at a site level, all in a single interface.

Automating Reporting and Submissions

TopBuild not only automated their data pipelines but also removed manual tasks from the reporting process such as submitting reports, processing mailers and billing in accordance with different federal and local regulatory requirements. By using Encamp, they added new sites, submitted hundreds of reports, and automated billing and mailers across different states and counties. This saves the team hundreds of hours every year so they can focus on more strategic ESG and compliance programs.

“Your solution is unique in that it’s the only one in the industry that can automate data collection and standardize it, while automating the reporting, submissions and fee payments. It’s been a game-changer for us.”

Impact beyond reporting: Being more innovative in other areas of compliance

According to TopBuild, one of the unexpected benefits to working with Encamp was becoming more forward-thinking in other areas of the business. As a result of reporting time savings, the team started to become more innovative and forward-looking and began looking at ways of automating other areas of compliance.